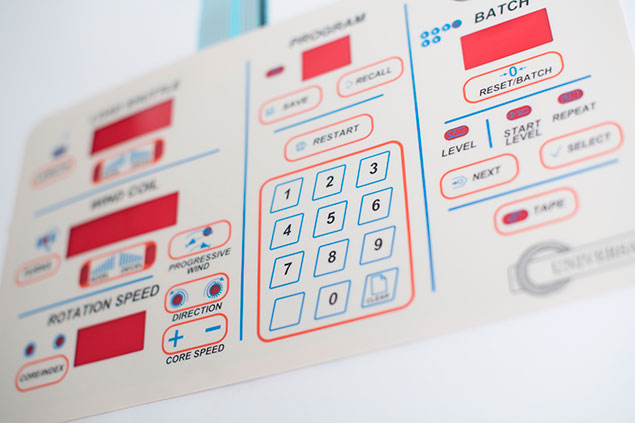

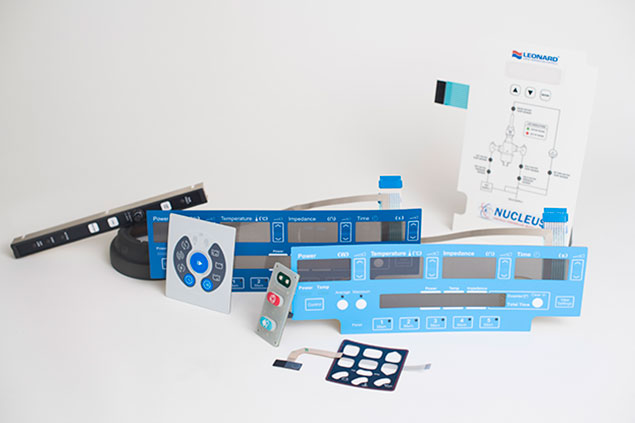

Custom Membrane Switches

Long now the de facto proven industry standard, the Membrane Switch is a low-profile layered construction of screen printed conductive inks and dielectric insulators on polymer substrates interleaved with specialized pressure sensitive adhesives. They can incorporate tactile and non-tactile switches, shielding, and even LEDs, resistors, and other components most would still believe to be the exclusive purview of thick Printed Circuit Boards. In special cases, where space or device population density become concerns, the Membrane Switch can even integrate the use of PCBs or Polyimide Flex circuitry for increased confidence and design resolution. Interface and connection options are just as customizable and varied.

Membrane Switch Data Sheets

Learn more on the specifics of membrane switch technology and which application is right for your project.

A top surface overlay directs the user to the specific functions beneath by means of printed graphics – endlessly customizable, brandable and as you͛ll see across this site, able to meet today͛s exacting challenges with a wide range of options and enhancements. From rugged, everyday use, indoors or outdoors, to showcase quality identifications and the ability to incorporate disparate but complementary technologies, the Membrane Switch can be tailored in fit, form, and function to satisfy your unique challenges.

Screenprint/Dow welcomes those challenges. With five decades of Industry leading experience and a vast pre- and post-digital age knowledge base of materials and practices, our dedicated team of Sales, Service, and Engineering professionals can work with you to identify and solve all your interface requirements with efficient and reliable solutions – not just custom designed, but investigated, researched, tested and verified in-house to meet all regulatory, environmental and aesthetic operational compatibility requirements and preferences. If there’s anything about your project that we can’t, or choose not to provide, you’ll know why and be presented up front – or at any time necessary before, during or after the design phase, with equal or superior alternatives to bring your concepts to operational reality.

Screenprint/Dow welcomes those challenges. With five decades of Industry leading experience and a vast pre- and post-digital age knowledge base of materials and practices, our dedicated team of Sales, Service, and Engineering professionals can work with you to identify and solve all your interface requirements with efficient and reliable solutions – not just custom designed, but investigated, researched, tested and verified in-house to meet all regulatory, environmental and aesthetic operational compatibility requirements and preferences. If there’s anything about your project that we can’t, or choose not to provide, you’ll know why and be presented up front – or at any time necessary before, during or after the design phase, with equal or superior alternatives to bring your concepts to operational reality.

We can provide full 2D and 3D design services, with full-color electronic or hard-copy press proofs of Graphics and circuitry. Our state-of-the-art Direct-to-Screen and Direct-to-Plate processes eliminate generational loss of quality from older, less-accurate film based systems. Screenprint/Dow can even reverse-engineer existing legacy key panels to update and improve them to meet all modern sensibilities, current specifications and regulatory requirements when necessary. All our projects are fully documented in-house and the information kept readily available for future use, modifications, or quality assurance.

We can provide full 2D and 3D design services, with full-color electronic or hard-copy press proofs of Graphics and circuitry. Our state-of-the-art Direct-to-Screen and Direct-to-Plate processes eliminate generational loss of quality from older, less-accurate film based systems. Screenprint/Dow can even reverse-engineer existing legacy key panels to update and improve them to meet all modern sensibilities, current specifications and regulatory requirements when necessary. All our projects are fully documented in-house and the information kept readily available for future use, modifications, or quality assurance.

If you͛d like to know more, please feel free to explore our website, or contact us directly at your convenience!